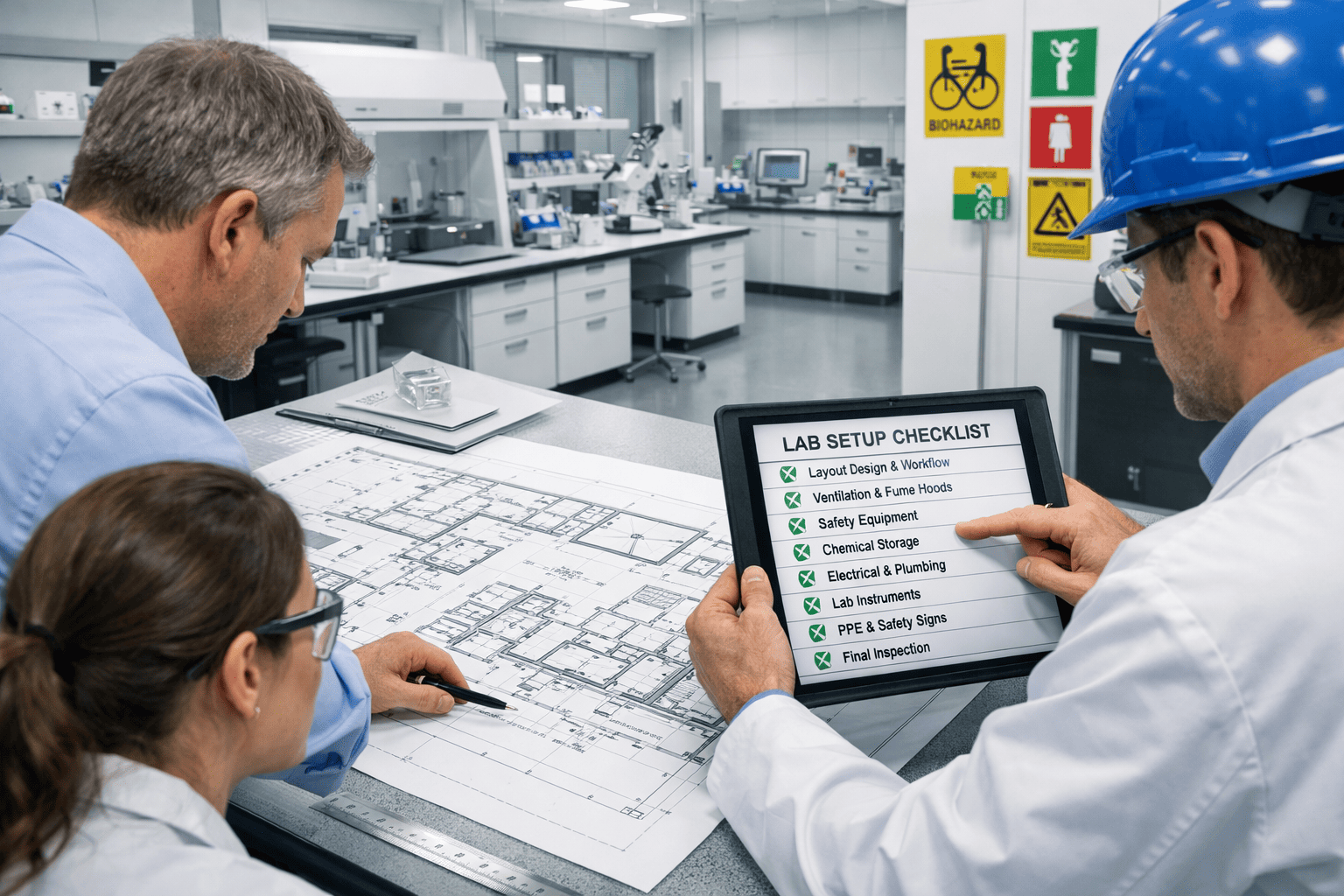

Types of Fume Hoods play a critical role in how safe and efficient a laboratory becomes. Every lab handles chemicals differently, so there’s no “one-size-fits-all” solution. Picking the wrong model can lead to poor airflow, contamination, and even serious health risks. The problem is—most laboratories don’t know which type they actually need. So let’s break it down clearly, step by step, in simple language. By the end, you’ll know exactly which fume hood suits your laboratory setup.

Why Fume Hoods Matter

A fume hood is not just equipment—it’s your first line of defense against toxic fumes, harmful vapors, acids, solvents, and heat. It protects:

- The user working at the workstation

- The environment inside the lab

- The materials being tested

For real project references, you can explore:

- chameza.in – turnkey laboratory solutions

- labturnkey.in – customized laboratory setup provider

- labcreator.in – lab furniture & equipment manufacturer

These websites show how fume hoods are actually implemented in industrial-grade laboratories.

Main Purpose of a Fume Hood

The system pulls air away from the user, dilutes it, and safely exhausts it outside. This prevents exposure to toxic substances. But every lab has different requirements. Research labs need precise airflow control. Pharma labs need contamination-free environments. Educational labs need budget-friendly options.

This is why choosing the right type is important—not all fume hoods are built for the same tasks.

Types of Fume Hoods (Explained Clearly)

Below are the most widely used models across industries. Each serves a different purpose.

-

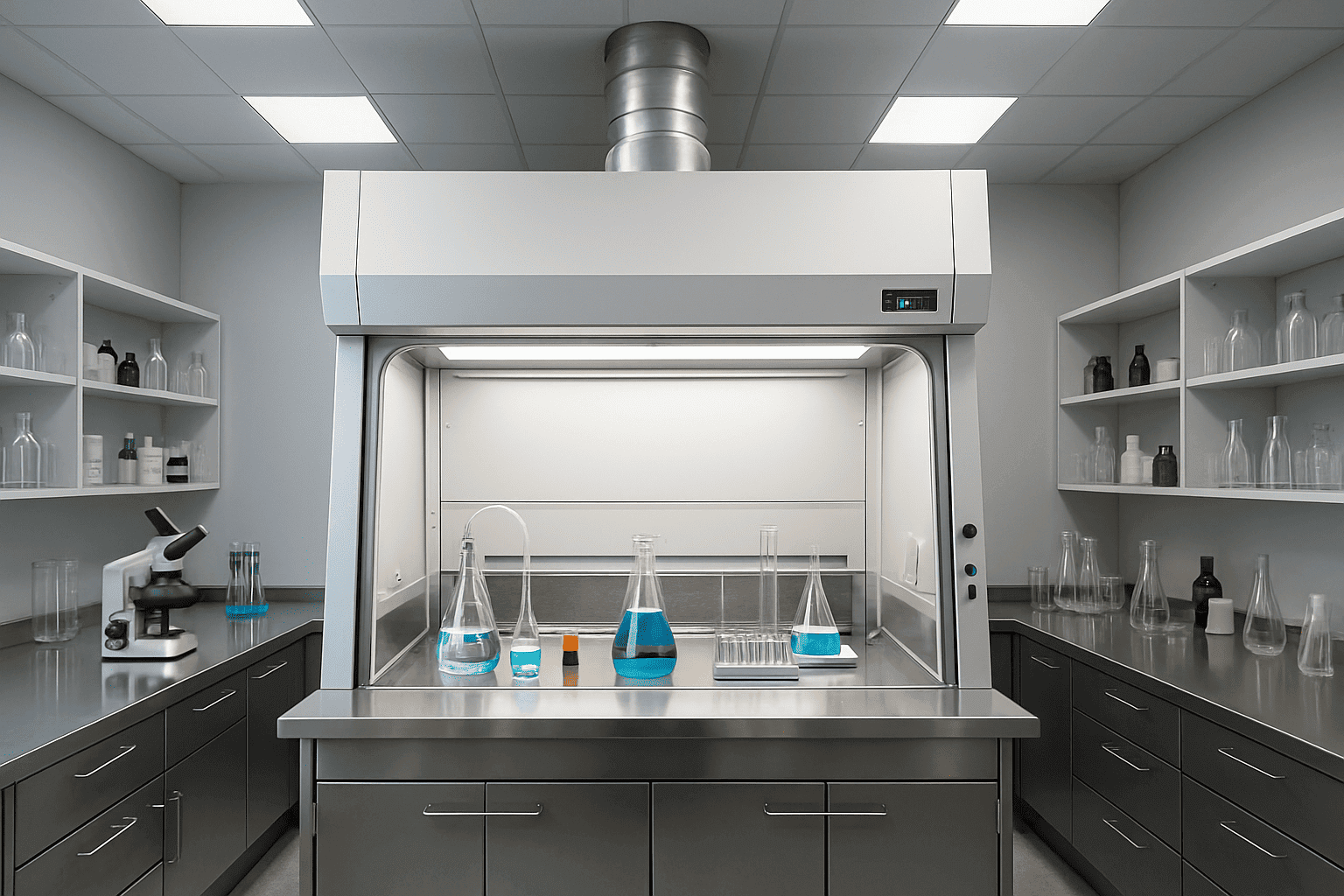

Ducted Fume Hood

This is the most traditional and widely used style. It connects to a building’s HVAC system with a dedicated duct. Harmful gases are flushed outside the building completely.

Best For:

✔️ Heavy chemical use

✔️ Industrial laboratories

✔️ High safety requirements

Consider if:

• You have proper ventilation space

• You can handle installation costs and ductwork modifications

-

Ductless (Recirculating) Fume Hood

Instead of pushing air outside, it uses filters to clean and recirculate the air back into the room. No external ductwork required.

Best For:

✔️ Small labs

✔️ Educational institutions

✔️ Rental spaces

Key benefit: Portable. Install it wherever needed—no construction work.

-

Walk-In / Floor Mounted Fume Hood

This is for large equipment, distillation setups, machinery, or tall reactors. It stands on the floor instead of a tabletop.

Best For:

✔️ Pilot plants

✔️ Manufacturing

✔️ Process simulation

If your lab handles big volumes or large apparatus, this is likely the best match.

-

Canopy Fume Hood

Think of it as a “chimney-style” hood installed above the workstation. It captures rising heat, vapor, steam, or smoke.

Best For:

✔️ Hot processes

✔️ Boilers, ovens, or sterilization

✔️ Areas where fumes rise naturally

Simple design. Cost-effective. But not for chemical protection—it only handles heat and steam.

-

Variable Air Volume (VAV) Fume Hood

Most advanced system. Airflow changes depending on workload. It senses motion or sash height and adjusts automatically.

Best For:

✔️ Research labs

✔️ Chemical engineering

✔️ Cleanrooms

Expensive—but saves a lot of energy. Excellent long-term investment.

-

Biosafety Cabinet (Not a True Fume Hood)

Often confused with fume hoods—but they are different. Biosafety cabinets protect samples from contamination. They use laminar airflow. They’re common in microbiology labs.

Best For:

✔️ Biological specimen handling

✔️ Hospital labs

✔️ Virus / bacteria research

Important: They are NOT designed for chemical fumes.

Which Fume Hood Should You Choose?

Let’s match needs with options:

| Lab Use | Suggested Fume Hood |

| High chemical usage | Ducted / Walk-In |

| No installation space | Ductless |

| Thermal heat or fumes | Canopy |

| Advanced research | VAV |

| Biological samples | Biosafety Cabinet |

| Big equipment setup | Floor Mounted |

Key Factors to Consider Before Purchasing

- Type of chemicals used

- Airflow requirements (CFM)

- Volume of usage – heavy or occasional

- Space and duct availability

- Maintenance cost

- Energy consumption

Most Indian laboratories fail to plan for future needs. They choose a model only for current use—but lab requirements grow. Choose wisely.

Common Mistakes to Avoid

❌ Installing without proper airflow testing

❌ Using wrong material (avoid mild steel for corrosive chemical labs)

❌ Ignoring noise level

❌ No maintenance schedule

❌ Forgetting safety alarms & face velocity checks

Safety Features You Should Always Include

- Airflow monitor

- Emergency shut-off valves

- Explosion-proof lighting

- Fire suppression compatibility

- Chemical-resistant interior material

Investment vs Cost – The Real Thinking

Many owners decide based only on price. Big mistake. A fume hood is not a purchase—it’s a safety guarantee. The correct model protects your staff, your investigations, and your equipment.

Here’s a better approach:

Decide based on risk level, not budget.

Think long-term: airflow + maintenance + safety standards.

Websites like labturnkey.in and labcreator.in already follow these industry standards while setting up turnkey labs. Use them as benchmarks.

Final Thoughts

Choosing the right fume hood isn’t about theory—it’s about matching your real lab requirements with the correct model. Analyze your chemistry level, equipment size, airflow needs, and safety protocols. Then decide.

A well-chosen fume hood becomes invisible—because it just works. A wrong one becomes a constant headache. If you’re planning a new lab or upgrading an existing one, you can explore industrial-grade references at chameza.in, labturnkey.in, and labcreator.in.