Designing Laboratory HVAC is one of the most important steps in creating a safe and efficient lab. A well-planned heating, ventilation, and air conditioning layout protects people, equipment, and experiments. It controls temperature and humidity, removes harmful fumes, and keeps clean areas from being contaminated. If you get it wrong, you may face safety risks, uncomfortable working conditions, and serious compliance issues. If you get it right, your lab will run smoothly, reliably, and cost‑effectively for years.

Why Lab Ventilation Is Different from Ordinary Buildings

Laboratories are not like homes or standard offices. They often handle:

- Hazardous chemicals and vapors

- Biological agents and microorganisms

- Sensitive instruments that need stable conditions

- Clean or controlled environments for testing and research

Because of this, a lab’s ventilation design has to do much more than just provide fresh air. It has to:

- Remove fumes, vapors, and airborne contaminants

- Maintain specific temperature and humidity levels

- Control air direction between rooms (pressure control)

- Support safety equipment such as fume hoods and biosafety cabinets

When planning your lab, treat ventilation as a core safety system, not just a comfort feature.

Airflow, Pressure, and Zoning: The Heart of Lab Ventilation

A successful lab ventilation design focuses on how air moves through the building. Three concepts are critical:

-

Directional Airflow

Air should flow from cleaner zones to more hazardous zones. For example, air should move:

- From corridors into labs

- From general labs into high‑hazard or high‑containment areas

- Towards exhaust points, not towards doors and escape routes

This reduces the risk of contaminants moving into safe areas.

-

Pressure Control

To achieve good directional airflow, you must control room pressure:

- Negative pressure rooms: Air is pulled into the room and exhausted outside. Used for chemical labs, infectious disease labs, and rooms with strong odors.

- Positive pressure rooms: Air is pushed out of the room into surrounding spaces. Used for cleanrooms, some QC labs, and sensitive instrument rooms.

Pressure differences are usually small but must be stable and constantly monitored.

-

Zoning the Lab Space

Divide the lab into zones based on function and risk:

- General lab areas

- High‑hazard or high‑containment rooms

- Clean or low‑particle environments

- Support areas (storage, corridors, change rooms)

Each zone can then have its own airflow, pressure, and filtration requirements. Good zoning helps you keep energy use under control while still meeting safety needs.

Key Design Considerations for Laboratory Ventilation

When planning advanced HVAC Systems for a lab environment, consider these factors early in the design process:

-

Safety and Hazard Assessment

Before drawing layouts, identify:

- Types and quantities of chemicals

- Whether biological agents will be used, and at what biosafety level (BSL)

- Equipment that generates heat, moisture, or airborne particles

This assessment will drive decisions about exhaust rates, filtration, and room pressurization.

-

Air Change Rates

Labs generally require higher air change rates than offices. The right number depends on:

- Type of lab (chemical, microbiology, clinical, QC, teaching lab)

- Presence of fume hoods and other exhaust devices

- Regulatory guidelines and risk level

Higher air changes mean more safety but also more energy use. The design must balance both.

-

Fume Hoods and Local Exhaust

Fume hoods, snorkel arms, and other local exhaust systems remove contaminants right at the source. Consider:

- The number and size of hoods

- Their location for smooth airflow and easy access

- Diversity factor (how many will be in use at the same time)

- Whether to use constant volume or variable air volume (VAV) hoods

These choices can greatly affect duct sizing, fan capacity, and operating costs.

-

Temperature, Humidity, and Comfort

User comfort is important for productivity, but in labs it also affects:

- Stability of experiments

- Performance of instruments

- Storage of reagents and samples

Define the temperature and humidity range early. Some rooms may need tighter control than others, such as calibration labs or instrument rooms.

-

Filtration and Air Quality

Laboratories may require:

- High‑efficiency particulate air (HEPA) filters for biological or cleanroom areas

- Chemical filtration (e.g., activated carbon) for certain contaminants

- Multi‑stage filters to protect both people and equipment

Good filtration reduces contamination risks and keeps sensitive instruments functioning properly.

Energy Efficiency and Operational Costs

Lab ventilation systems can be large energy consumers due to high air change rates and 24/7 operation. Smart design can significantly reduce running costs:

- Use heat recovery systems to reclaim energy from exhaust air

- Apply demand‑controlled ventilation (adjusting airflows based on occupancy or sensor readings)

- Use VAV controls with fume hoods and room airflow

- Properly insulate ductwork and carefully seal the system

Spending more time in design to optimize energy use can save substantial money over the life of the facility.

Controls, Monitoring, and Automation

Modern labs need intelligent building management and control:

- Room pressure monitors with alarms

- Sensors for temperature, humidity, and airflow

- Automatic adjustment of airflows when hoods open or close

- Integration with fire and emergency systems (e.g., purge modes)

With digital controls and monitoring, facility teams can spot problems early, adjust settings remotely, and maintain safe conditions at all times.

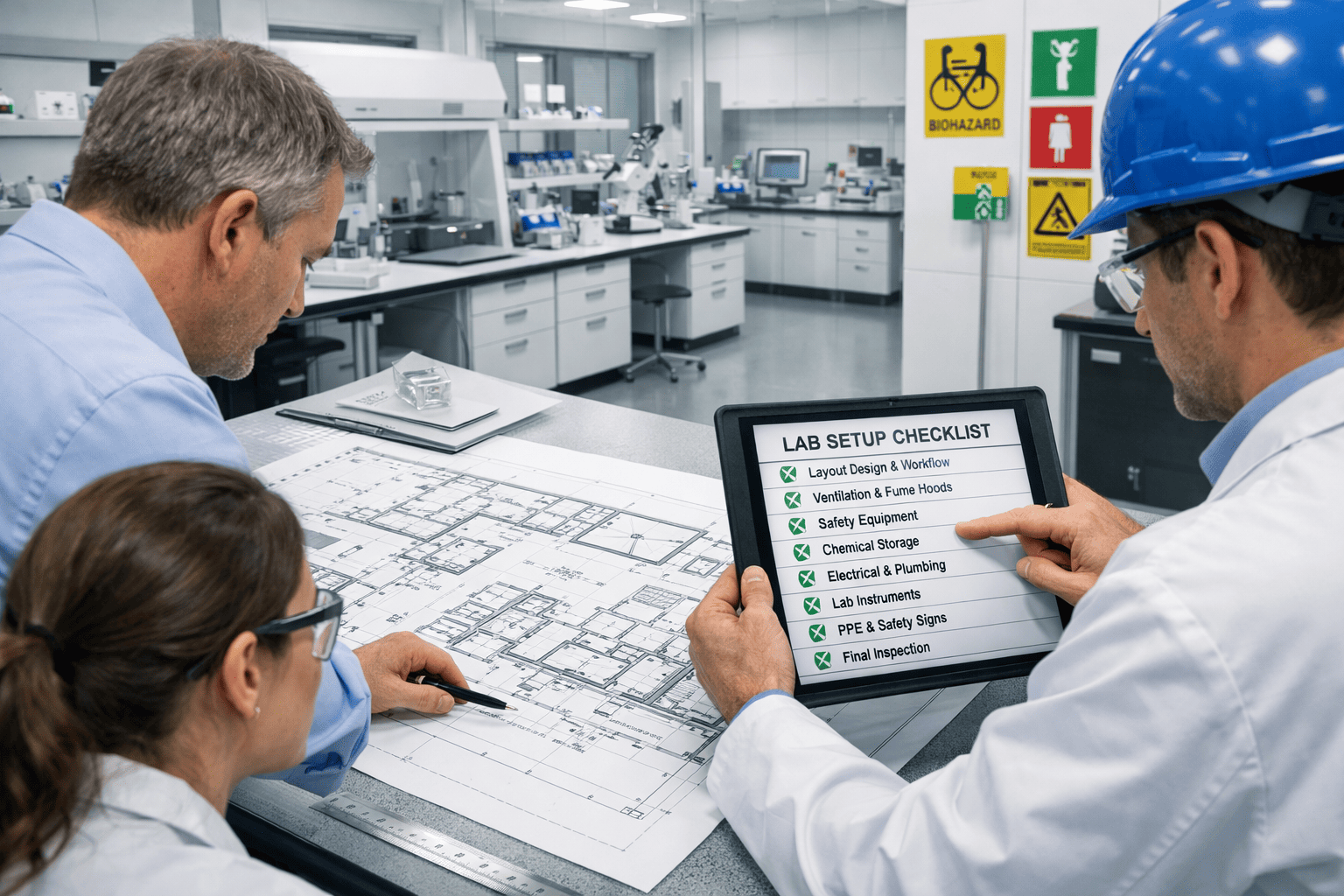

Planning, Installation, and Commissioning

The design is only the first step. How you handle HVAC Setup and commissioning will determine whether the system actually performs as intended.

Key steps include:

- Coordination in design stage

Architects, lab planners, mechanical engineers, safety officers, and end users must all be involved. Room layouts, equipment lists, and anticipated workflows should be fixed as early as possible. - Quality installation

Duct routing, sealing, insulation, and equipment placement all impact real‑world performance. Poor installation can lead to noise, leaks, or unstable room pressures. - Thorough testing and balancing

After installation, the system must be tested and balanced:- Verify air change rates and pressure differentials

- Test fume hood containment performance

- Confirm alarm set‑points and control logic

- Documentation and training

Provide clear manuals and training for facility staff and lab users. Everyone should understand the basics of how the system works and what alarms mean.

Codes, Standards, and Local Requirements

Laboratory mechanical design must follow:

- Local building codes and fire codes

- Occupational health and safety regulations

- Standards such as ASHRAE guidelines and, where relevant, biosafety or cleanroom standards

Depending on your region and lab type, there may be specific rules for air change rates, exhaust discharge, filtration, and emergency controls. Always work with qualified professionals who understand these requirements.

Getting Professional Support

Because lab ventilation design is complex, many organizations work with specialized lab designers and turnkey solution providers. In India, for example, companies like chameza.in, labturnkey.in, and labcreator.in focus on planning, building, and equipping laboratories across industries. Such partners can help you:

- Translate safety and compliance needs into technical requirements

- Optimize layouts for workflow and future expansion

- Select appropriate equipment, controls, and materials

- Coordinate between civil, mechanical, electrical, and lab furniture works

Conclusion

A well‑designed laboratory ventilation and HVAC plan is essential for safety, comfort, compliance, and long‑term operating efficiency. By understanding airflow, pressure control, zoning, equipment needs, and regulatory expectations, you can create a lab environment that supports both people and science.

Take the time to plan carefully, involve the right experts, and treat your ventilation and HVAC systems as core safety infrastructure. When this foundation is strong, your laboratory will be safer, more reliable, and ready to grow with your research and testing needs.