Maintaining a safe laboratory environment starts with proper understanding and consistent practice of Fume Hood Safety. Fume hoods are essential engineering controls designed to protect lab personnel from hazardous fumes, vapors, and chemicals. However, simply having a fume hood is not enough its effectiveness depends heavily on how correctly it is used. This article provides detailed guidelines, Do’s and Don’ts, and best practices that every laboratory professional must follow while working with Fume Hoods.

Why Fume Hood Safety Matters

Laboratories often handle chemicals that release toxic gases, harmful particulates, and volatile vapors. A fume hood acts as a barrier between the user and these contaminants. When used incorrectly, the protection significantly reduces, exposing the user to risks such as chemical inhalation, burns, respiratory issues, or accidental chemical reactions. Practicing proper Fume Hood Safety ensures:

- Optimal protection from hazardous fumes

- Reduction in chemical exposure

- Controlled airflow inside the hood

- Safe handling and disposal of chemicals

- Compliance with safety regulations and audits

Understanding the Do’s and Don’ts of fume hood use is essential for maintaining both personal safety and the integrity of the workspace.

How Fume Hoods Work

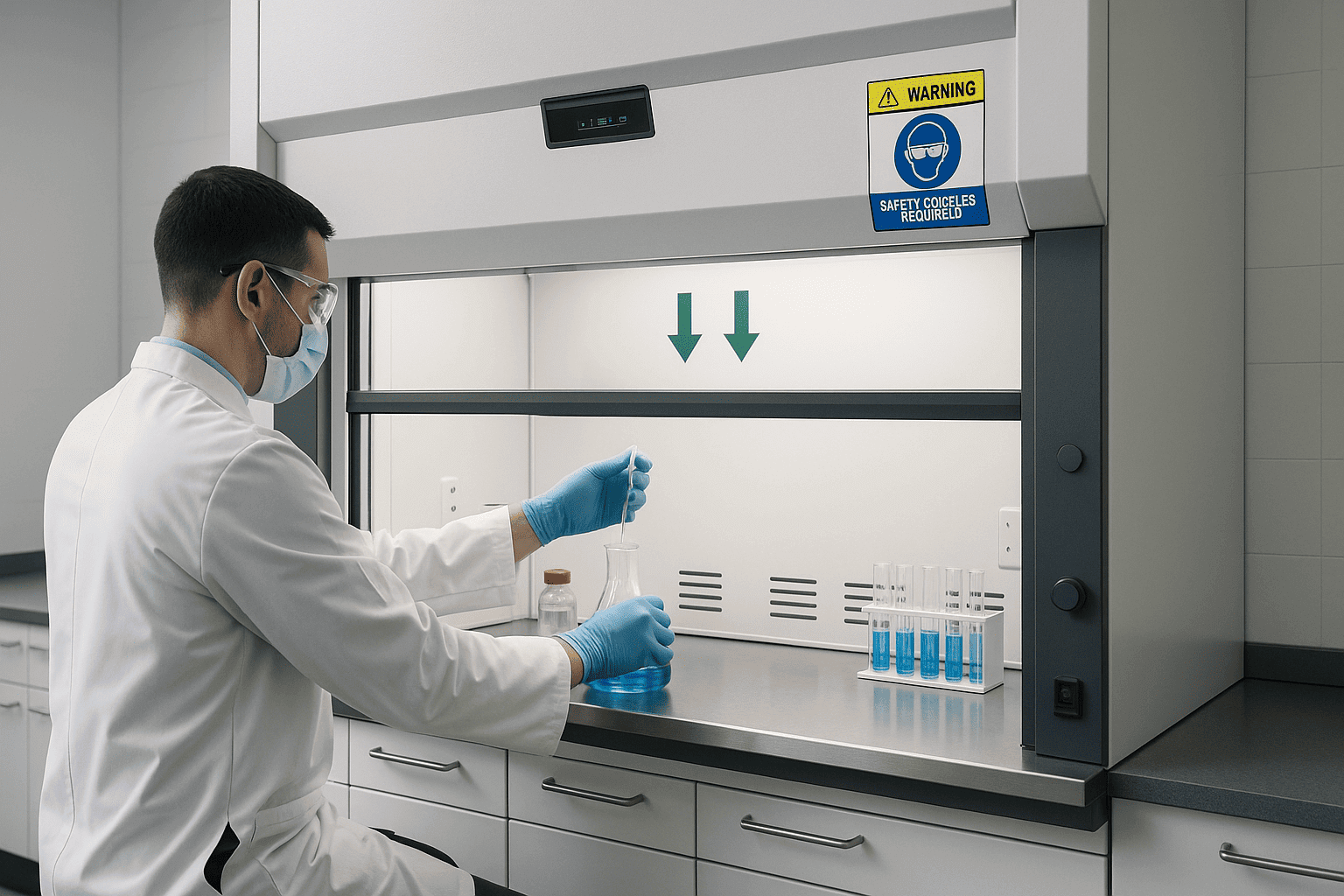

Fume Hoods function by drawing contaminated air away from the user through a controlled airflow system. The air is either filtered or exhausted outside the facility. The sash (the glass window) protects users from splashes and provides a physical barrier. Proper airflow, sash height, and user behaviour are the key elements that determine how effectively a fume hood performs.

Do’s of Fume Hood Safety

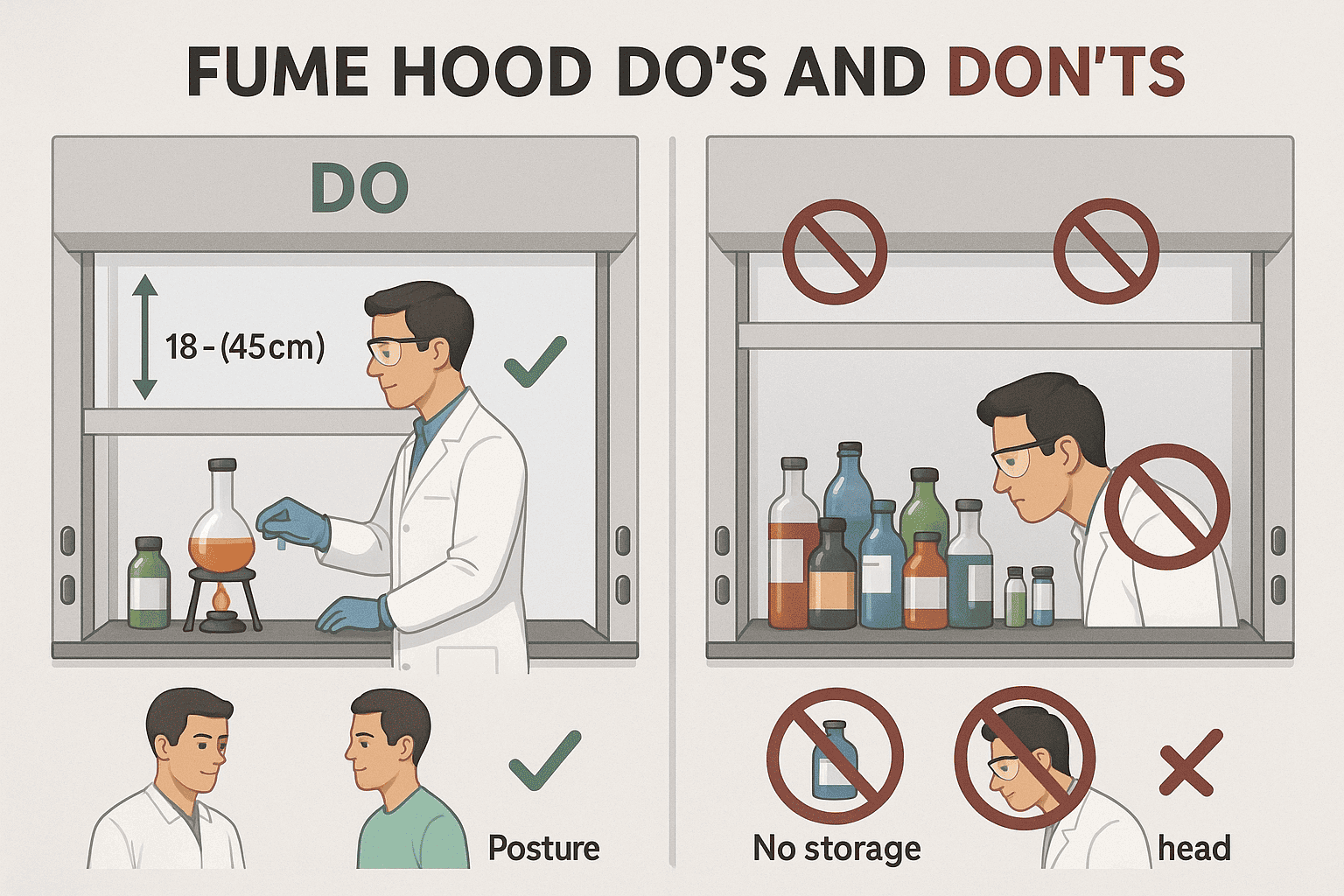

1- Always Work with the Sash at the Recommended Height

One of the most important Fume Hood Safety guidelines is to keep the sash at the suggested operating height—usually marked on the hood. This ensures maximum protection and optimal airflow. A lower sash height also acts as a physical shield in case of accidental splashes or minor explosions.

2- Position Materials at Least 6 Inches Inside

Place all chemicals, equipment, and containers at least six inches from the front edge. Keeping everything deep inside creates a smooth airflow pattern and reduces turbulence at the hood opening.

3- Keep the Hood Clean and Uncluttered

An organized fume hood ensures effective containment. Too many objects inside disrupt airflow and reduce performance. Always remove unnecessary tools, wipe spilled residues, and maintain a clear surface for safety and efficiency.

4- Conduct Regular Airflow Checks

Before starting any experiment, verify that the airflow monitor is functioning. Some Fume Hoods have digital indicators while others use a simple airflow meter. Regular checks ensure the hood is operating at the required face velocity.

5- Use Appropriate Personal Protective Equipment (PPE)

Even while working in a fume hood, PPE is essential. Always wear:

- Lab coat

- Safety goggles

- Chemical-resistant gloves

- Closed-toe shoes

This is a fundamental part of Fume Hood Safety because the hood protects you from fumes, but PPE protects you from spills.

6- Perform Procedures Slowly and Smoothly

Sudden movements disturb airflow and may pull contaminated air toward the user. Always work gently and avoid quick hand motions around the hood opening.

7- Ensure Proper Lighting Inside the Hood

Good visibility prevents accidental spills and mistakes. Keep the hood lights functional and the glass clean.

8- Close the Sash When Not in Use

Once you finish working, close the sash completely. This protects the lab environment, reduces energy consumption, and maintains safe conditions.

Don’ts of Fume Hood Safety

1- Don’t Place Large Equipment at the Front

Large instruments create turbulence and block airflow. Position bulky equipment at the back of the hood and place them on risers to allow proper ventilation underneath.

2- Don’t Store Chemicals Permanently Inside the Hood

A common mistake is using Fume Hoods for storage. This not only disrupts airflow but also increases the risk of fire or chemical exposure. Store chemicals in approved cabinets instead.

3- Don’t Work with Your Head Inside the Hood

This is one of the most critical Do’s and Don’ts to remember. Never insert your head into the hood opening. Doing so directly exposes you to dangerous fumes and defeats the purpose of the hood.

4- Don’t Block Air Vents

Air slots at the back and sides help maintain consistent airflow. If you block them with equipment or containers, the hood loses efficiency.

5- Don’t Ignore Alarm Indicators

If the airflow alarm sounds, stop working immediately. Investigate the issue or call a technician. Continuing to work without proper airflow is unsafe.

6- Don’t Open the Sash Too High

Opening the sash beyond the recommended height changes the face velocity, allowing fumes to escape. This is a major violation of Fume Hood Safety.

7- Don’t Rush Your Work

Fast hand movements, rapid heating, or hurried pouring can cause splashes, spills, or disrupted airflow. Maintain patience and precision.

8-Don’t Use the Fume Hood for Non-Chemical Tasks

Avoid using Fume Hoods for tasks like writing notes, storing lunch, or keeping personal belongings. The hood is designed only for chemical handling and hazardous procedures.

Best Practices for Long-Term Fume Hood Maintenance

To ensure maximum protection, follow these long-term guidelines:

1- Schedule Annual Certifications

Technicians should inspect and certify the hood every year for airflow efficiency, sash performance, and structural integrity.

2- Train All New Users

Any new lab personnel must undergo proper training on Fume Hood Safety and the basic Do’s and Don’ts before they start working.

3- Check for Physical Damage

Cracks, broken sashes, or damaged seals compromise safety. Report issues immediately.

4- Maintain Good Housekeeping

Spills, dust, and residue affect airflow and create contamination risks. Clean regularly.

Conclusion

A laboratory’s safety depends significantly on how effectively Fume Hoods are used. Practicing strong Fume Hood Safety habits, understanding the essential Do’s and Don’ts, and maintaining proper airflow and cleanliness help reduce risks and protect lab personnel. A well-maintained and correctly operated fume hood ensures a safer work environment, boosts productivity, and helps comply with regulatory standards. Following these detailed tips will not only enhance overall lab safety but also foster a culture of responsibility and professionalism.