When you’re dealing with chemicals in any laboratory or industrial setting, safety isn’t optional — it’s the foundation of every process. One of the most critical elements of a safe workspace is proper chemical storage. That’s where chemical storage cabinets come into play. These cabinets are specifically designed to protect both your staff and your facility from hazardous spills, leaks, or fires that can result from improper handling or storage of chemicals.

Let’s break down the key safety features you should look for when selecting the right cabinet for your lab or facility.

1- Fire Resistance and Construction Material

The first thing to check is the cabinet’s construction. A reliable chemical storage cabinet should be built from materials that can resist heat and fire for a specific duration, usually tested according to international standards. Most quality cabinets are made from double-walled steel with an air gap between the walls to minimize heat transfer during a fire.

Doors should be self-closing and have tight-fitting seals to prevent flames or vapors from escaping. Fire resistance isn’t just a feature—it’s a legal requirement in many regions, depending on the types of chemicals stored. Look for models that meet recognized chemical safety cabinet standards, ensuring they’ve passed fire endurance tests and comply with regulations.

2- Ventilation System

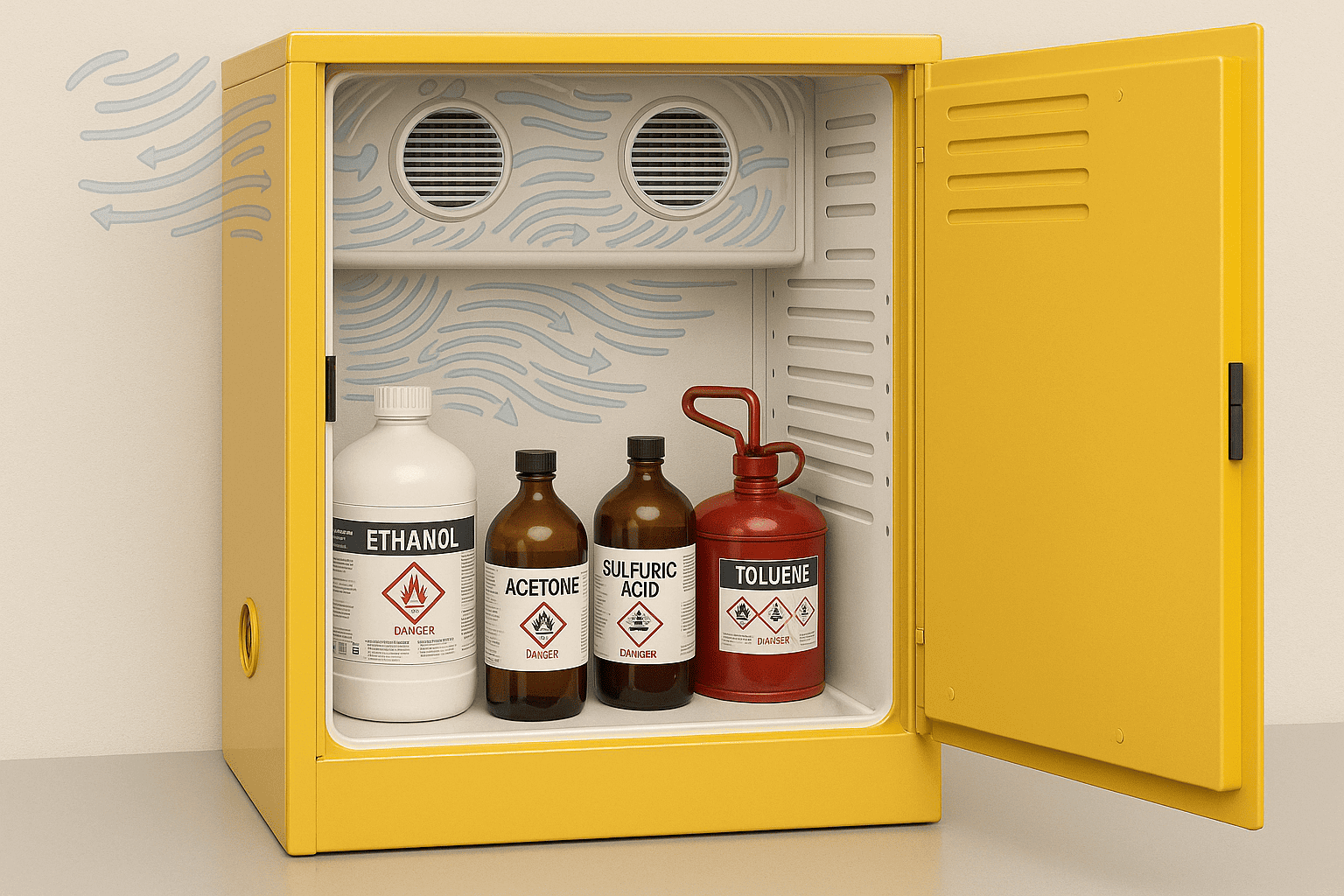

Chemical fumes and vapors can accumulate quickly inside storage units, posing a serious health risk. A good cabinet design allows for proper ventilation, either through built-in exhaust ports or optional ducting systems.

Modern cabinets include flame arrestors on the vents, which prevent external ignition sources from entering the cabinet through ventilation ducts. This not only protects the contents but also helps maintain a safer environment around the cabinet.

If your lab handles flammable or volatile chemicals, proper ventilation isn’t just a nice-to-have — it’s essential.

3- Leak-Proof Sump and Spill Containment

Spills happen — even in well-managed labs. That’s why spill containment features are critical. Look for cabinets with an integrated leak-proof sump at the base. This sump collects accidental drips or leaks, preventing chemicals from spreading across the floor and creating hazards.

The sump capacity should be sufficient to hold at least 10% of the total stored volume or the volume of the largest container inside, whichever is greater. This containment feature makes cleanup easier and keeps both staff and the environment safe from chemical exposure.

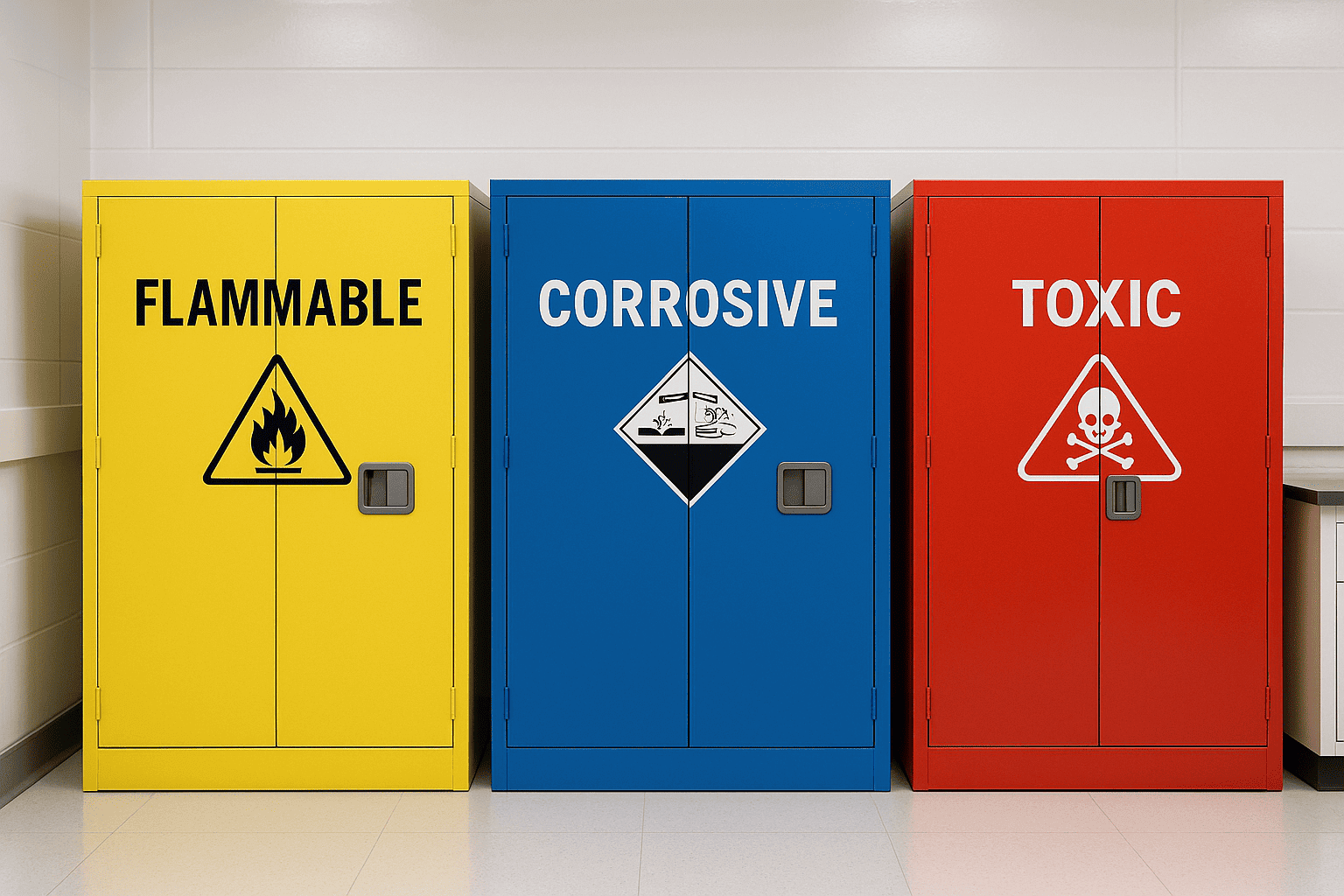

4- Clearly Visible Labels and Color Coding

Identification plays a big role in safety. Cabinets should have clear, durable labels such as “Flammable,” “Corrosive,” or “Toxic” to indicate the type of chemicals inside. These labels help prevent mistakes during storage or handling, especially in large labs where multiple substances are used.

Color coding is another smart feature — for example, yellow for flammables, blue for corrosives, and red for toxic substances. Consistent labeling and color systems save time and can prevent accidents caused by confusion or misplacement.

5- Adjustable Shelving and Chemical Compatibility

Different chemicals come in different container sizes and forms. Adjustable or removable shelves allow flexibility for organizing these safely. The shelves should be corrosion-resistant and designed to prevent containers from tipping or sliding.

Compatibility is key — you can’t store acids and flammables in the same cabinet. Make sure the materials used in the shelving and lining are compatible with the chemicals you plan to store. Stainless steel or coated shelves are preferred for their durability and resistance to corrosion.

6- Locking Mechanism and Access Control

Unauthorized access to chemicals can be dangerous. A secure locking system ensures that only trained personnel can handle or retrieve materials from the cabinet.

Some advanced cabinets now come with electronic access systems that log user activity. While this may be overkill for small labs, it’s a valuable feature for larger facilities or research centers handling sensitive or high-risk materials.

7- Proper Ventilation Integration with Lab Design

Many laboratories overlook how their cabinets integrate with the overall ventilation system. It’s not enough for a chemical storage cabinet to have vent openings — it must be installed in a way that aligns with the room’s air handling setup.

Ducted cabinets, for example, connect directly to the lab’s ventilation system, while ductless ones rely on built-in filters. Choosing the right type depends on your space and the nature of your chemicals. Always consult with a safety engineer before installation to ensure compliance with chemical safety cabinet standards.

8- Grounding and Static Protection

If you’re storing flammable liquids, static electricity can be a real threat. Some cabinets come with grounding connectors that allow static discharge to be safely directed away. This prevents sparks that could ignite chemical vapors.

Grounding should be standard practice in any facility that handles volatile materials, especially when transferring liquids between containers.

9- Ergonomic Design and User Safety

A well-designed cabinet makes it easy to handle chemicals safely. Look for ergonomic features such as smooth-closing doors, easy-to-reach handles, and visible labeling at eye level.

This might sound minor, but reducing strain or confusion during handling can significantly lower the risk of accidents, especially in high-traffic or fast-paced lab environments.

10 – Compliance with Safety Standards

Finally, never overlook certification. Reputable manufacturers design their products to meet or exceed international standards such as OSHA, NFPA, or EN 14470-1. Compliance isn’t just about ticking a box — it’s proof that the cabinet has been tested for performance, fire resistance, and containment efficiency.

Before purchasing, check if your cabinet meets chemical safety cabinet standards specific to your country or industry. Certified products provide peace of mind and ensure you’re operating within safety regulations.